Approach

to

New

Technologies

Advanced tooth surface

correction technology

for tooth surface

grinding gears.

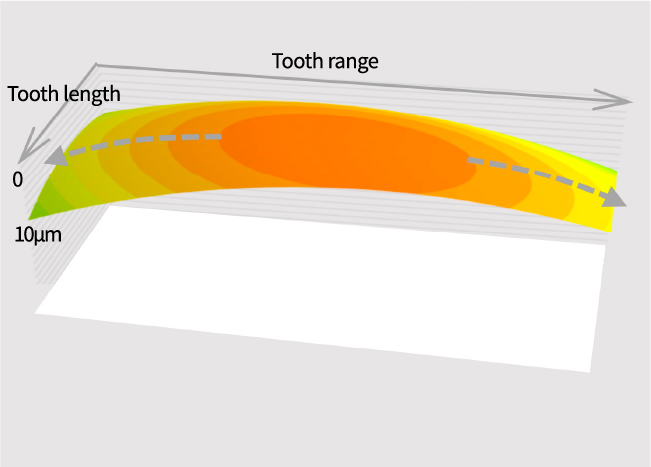

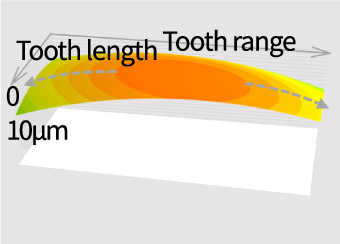

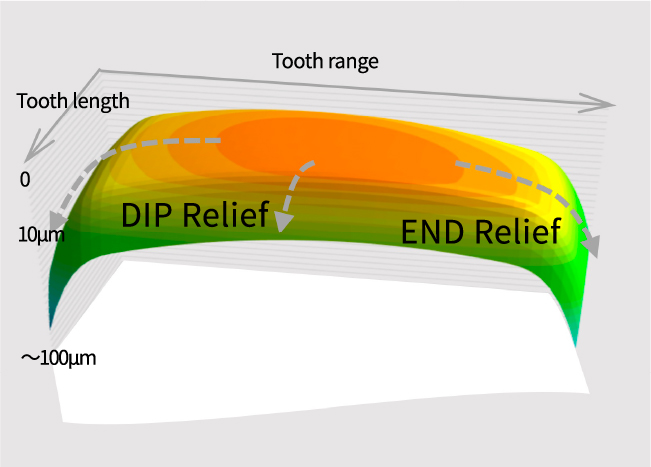

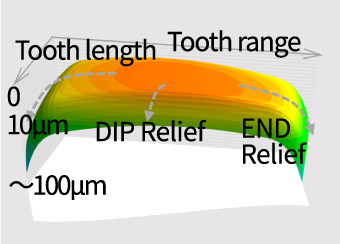

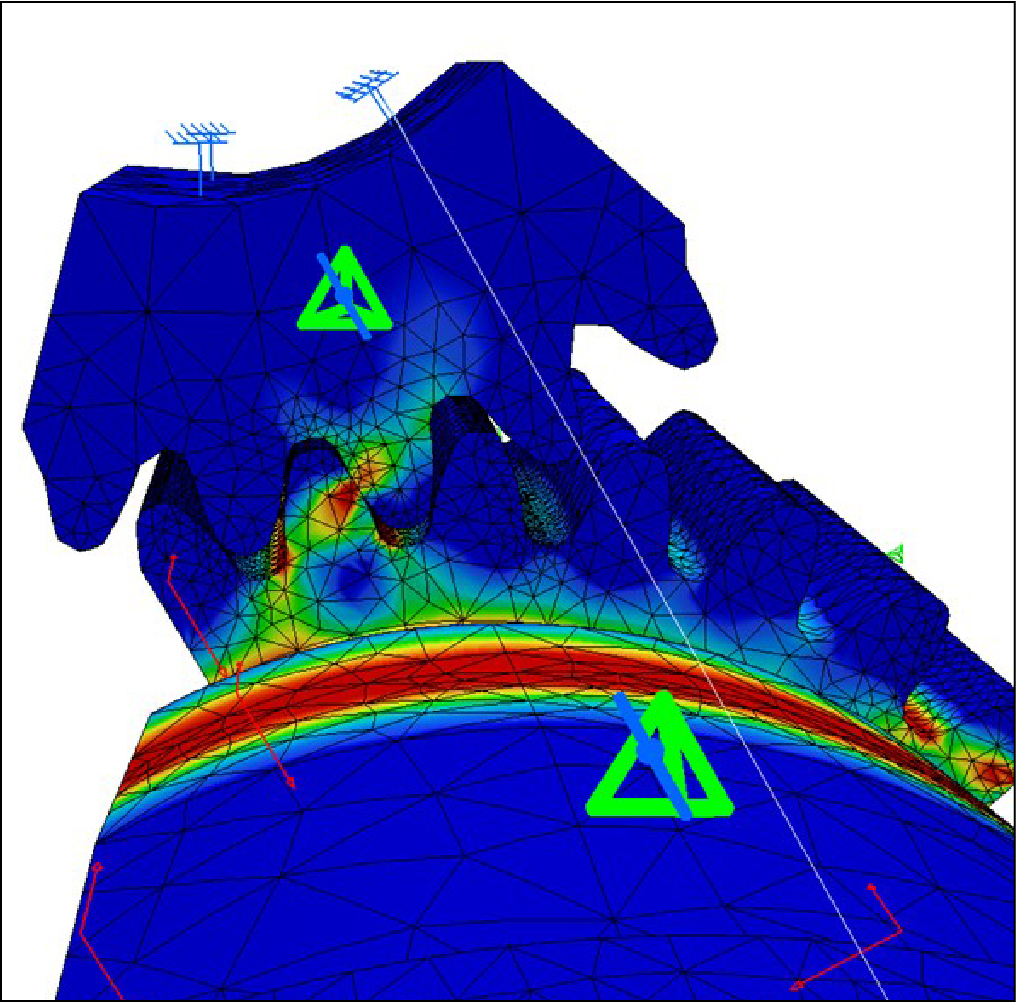

Gears transmit power by meshing and rotating with mating gears. To ensure smooth meshing, involute curves are often used for the tooth shape. When transmitting a large amount of force, the gears deform and fail to maintain their ideal shape, resulting in partial meshing of the tooth surfaces and the loss of smooth rotation transmission. This can result in problems such as noise and tooth damage.As a countermeasure, it is common to increase the gear size or add tooth surface modification such as crowning (a slight rise of a few microns) in advance to achieve the optimum tooth surface shape after deformation. However, this is not a panacea, since larger gear sizes make the equipment heavier and larger crowning amounts at the assumed maximum torque can cause noise under light loads.Therefore, 3D tooth surface modification is advocated, such as using a flat area in the center to avoid meshing noise under light loads, and smoothly rounding the tooth surface under high loads to avoid stress concentration on the edges.

-

Without modification

-

Crowning repair

-

3D modification=

Stress Reduction

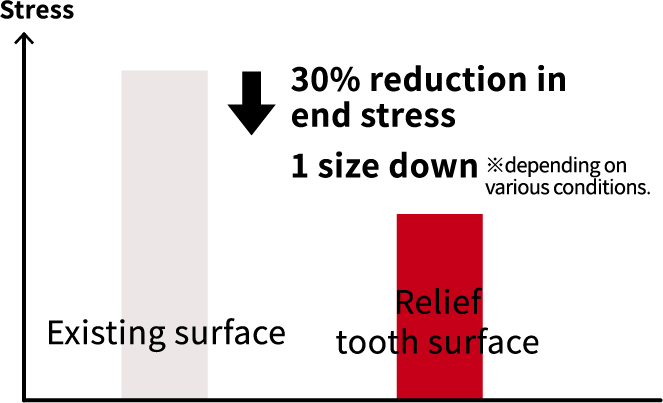

Effects of 3D tooth

surface modification

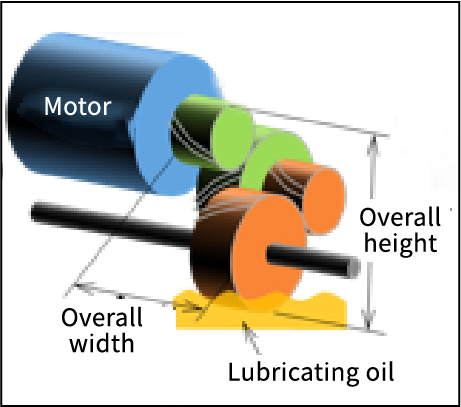

By applying 3D tooth surface modification, the size can be made smaller and lighter than conventional gears while maintaining the noise level, resulting in higher performance gears. It also contributes to CO2 reduction.

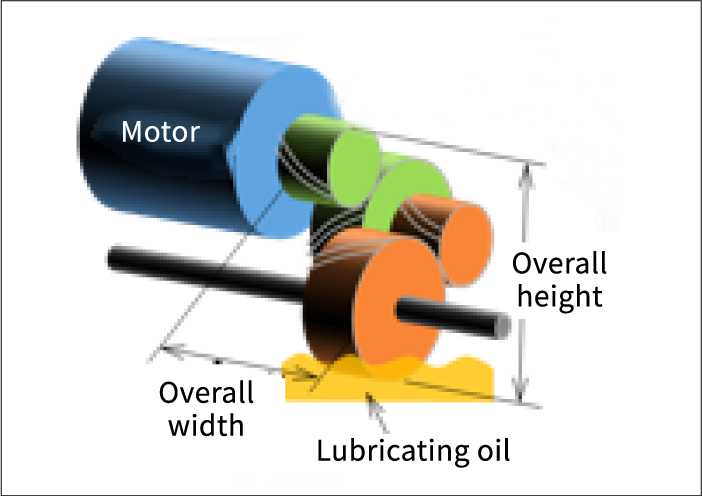

- Overall gearbox width reduction (10%)

by shortening tooth width. - Overall gearbox height reduced by 7%

due to gear diameter reduction. - Unit weight reduction due to gear

size reduction (20%). - Lower power consumption (loss reduction)

due to lower viscosity lubricating oil.

Effects of 3D tooth surface modification

based on desktop calculations

Gearbox

Simulation Technology

for Worm-like

Grinding

Wheel Gear Sharpening.

Reproduces the machined

tooth surface

on a cylindrical

gear grinder

in micron order

based on gear

origin /

tooling specifications.

Our self-developed software is packed with gear grinding technology cultivated over many years. We will partner with our customers to promote DX and bring innovation to their manufacturing.

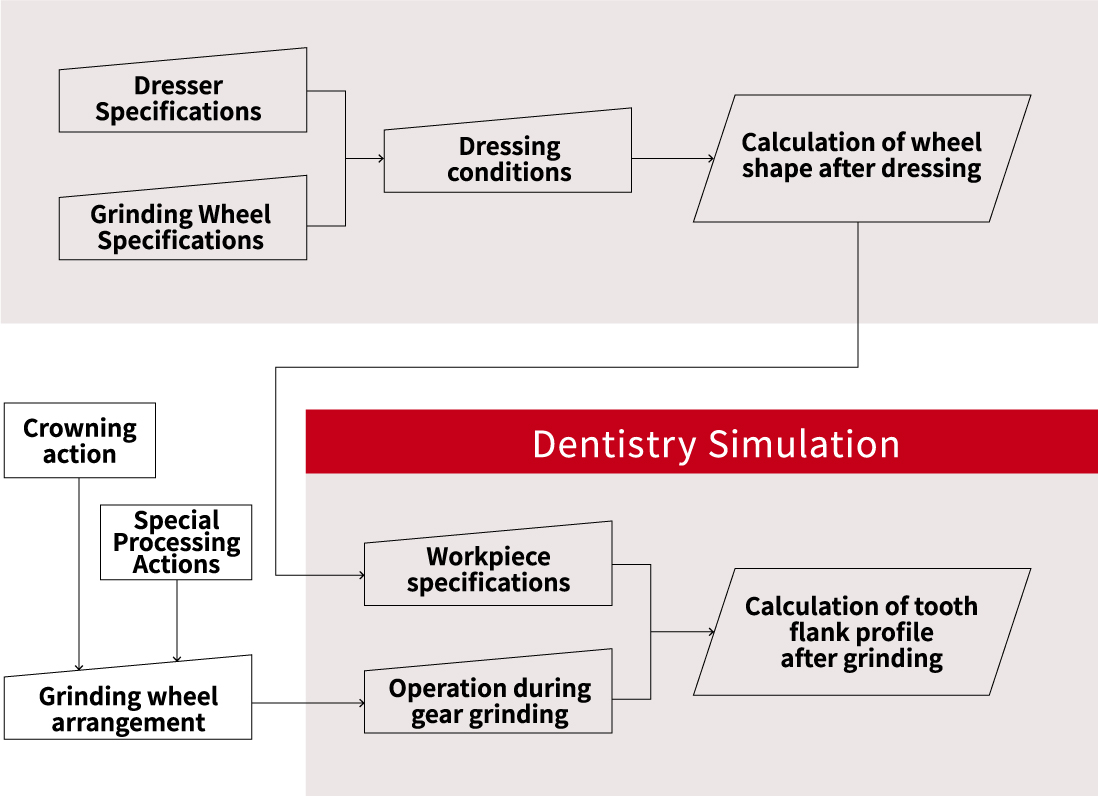

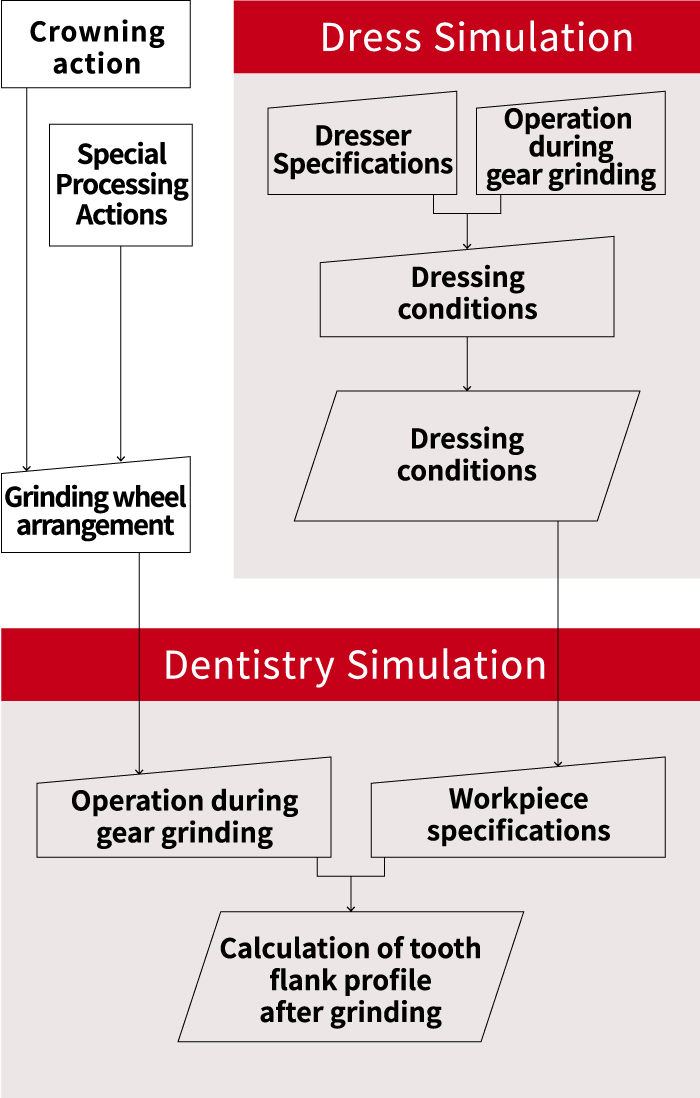

INPUT

- Workpiece

Specifications/ - Grinding

Wheel

Specifications/ - Dresser

Specifications/ - Dressing

Conditions/ - Machining

Conditions

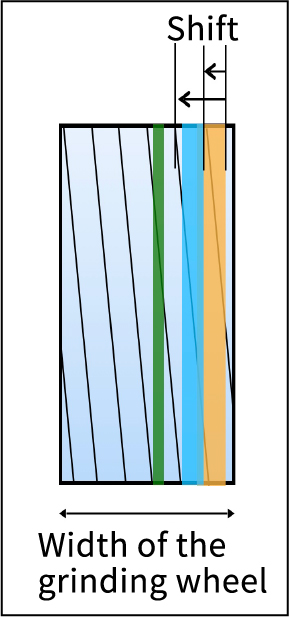

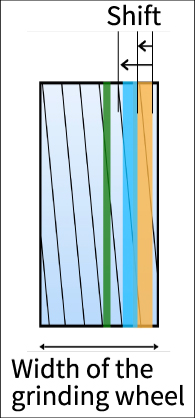

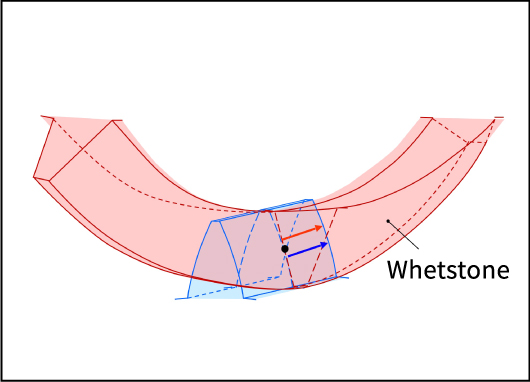

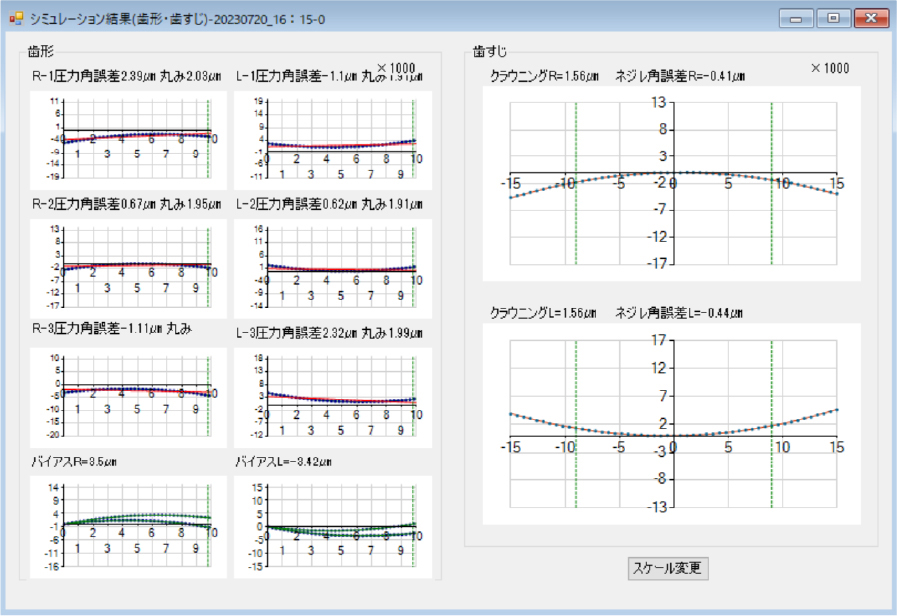

Dress Simulation

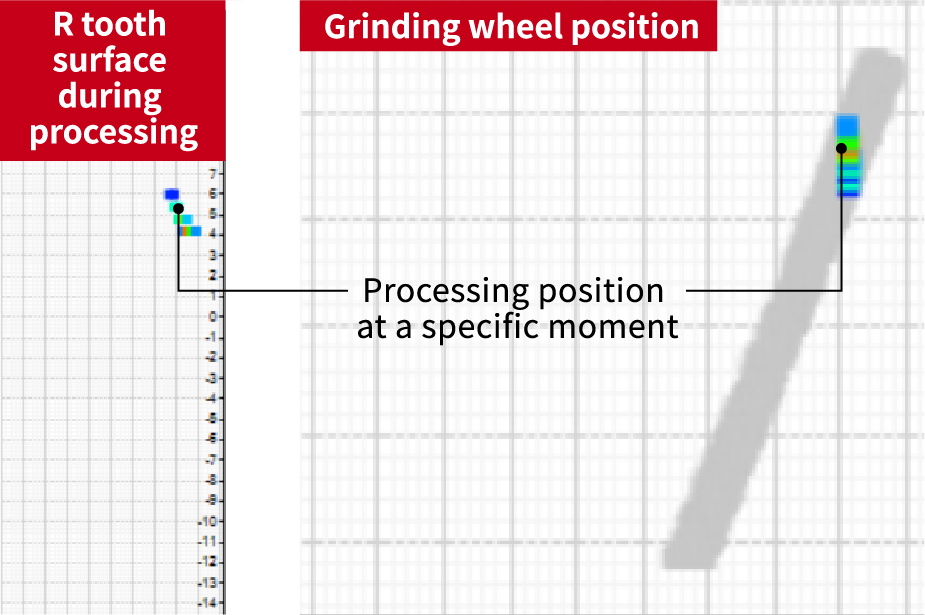

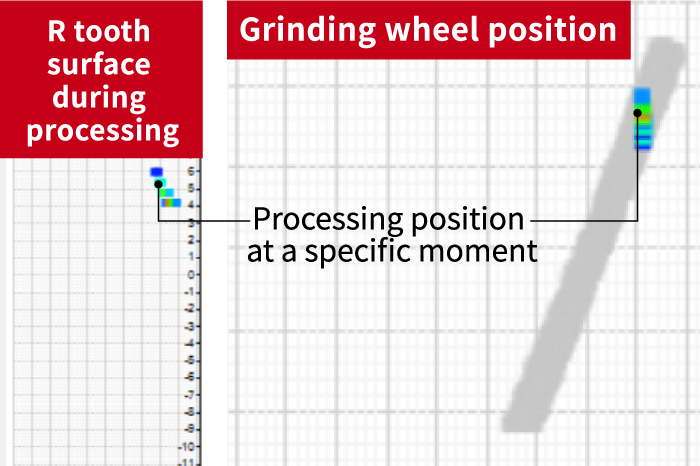

Image of Dress Simulation

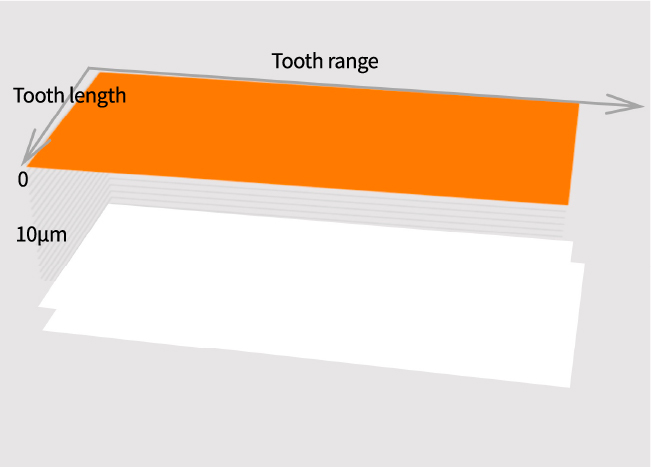

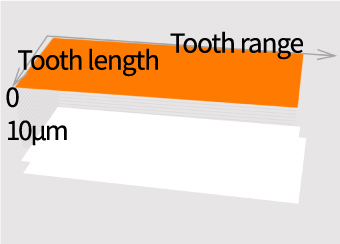

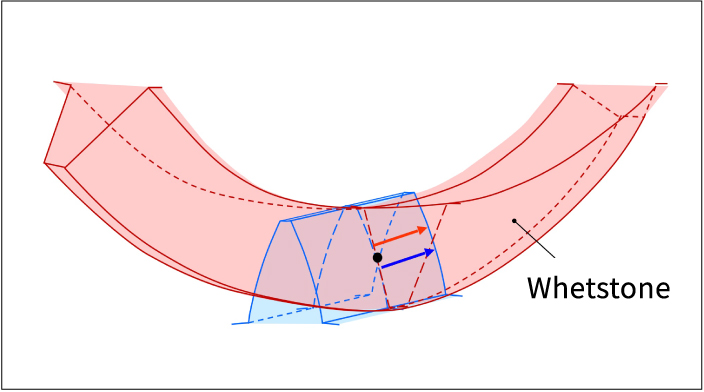

Image of

Dental Research Simulation

OUTPUT

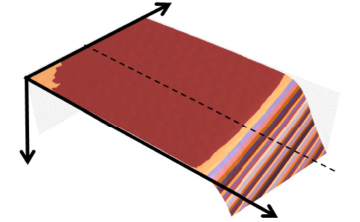

- Grinding

wheel shape/ - Tooth

surface shape/ - Where to use

boulders

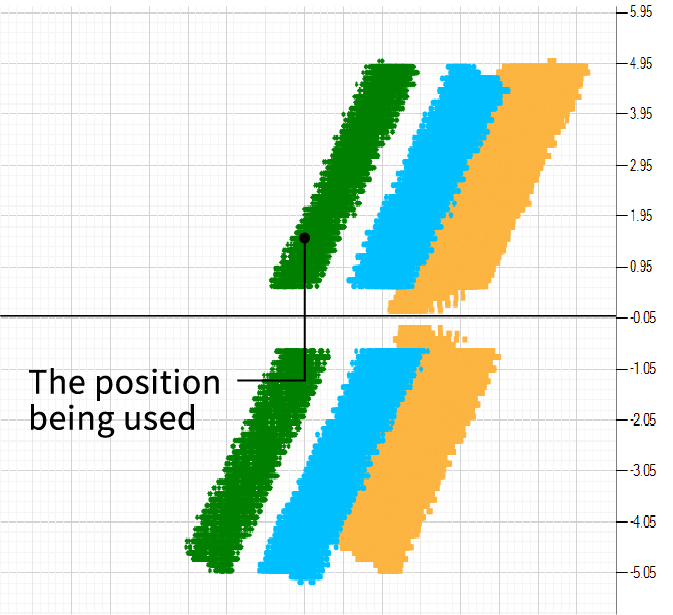

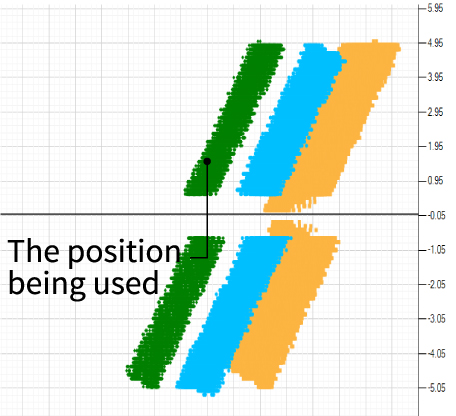

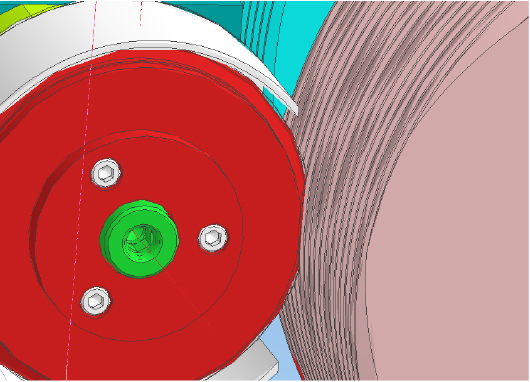

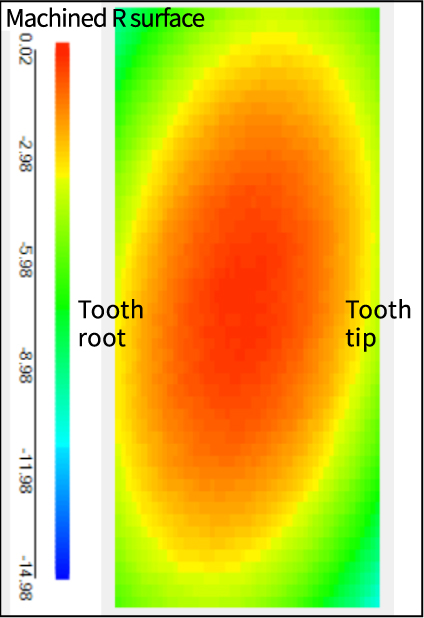

Shape of tooth flank

after machining

Where to use boulders

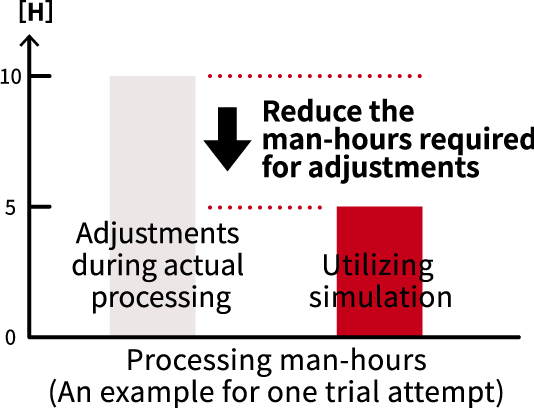

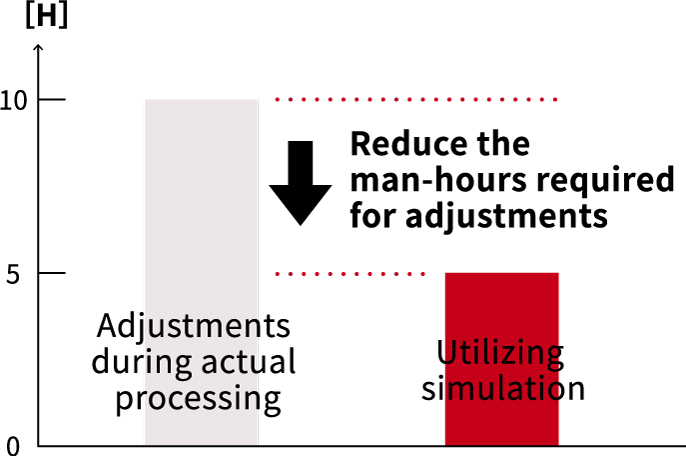

Effects of “GEAR simu”

It can solve issues with

tooth grinding processing.

1Confirmation of

processing shape.

We can also accommodate special processing operations. This can lead to a reduction in trial processing man-hours and a shortened lead time.

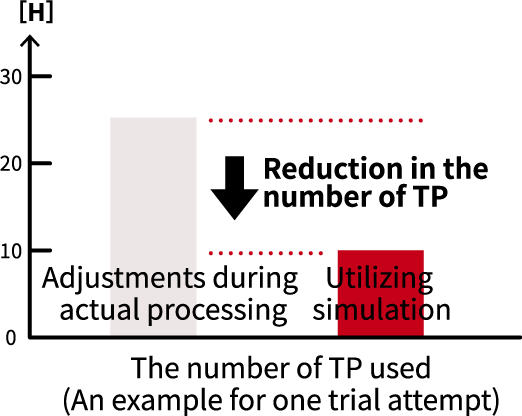

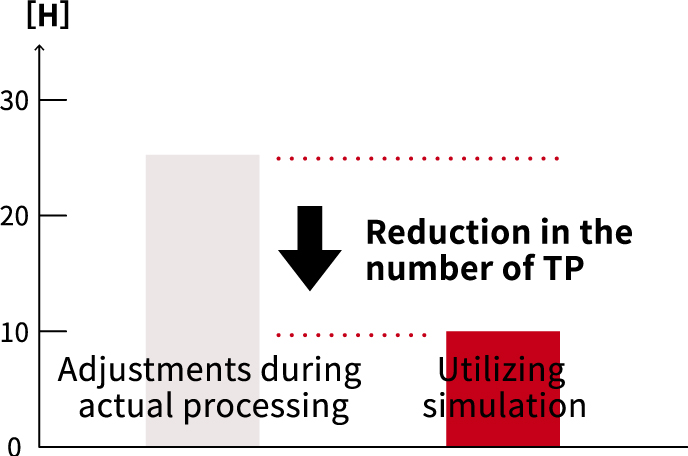

Processing man-hours

(An example for one trial attempt)

The number of TP used

(An example for one trial attempt)

2Positioning of the

grinding stone.

It is possible to optimize shift conditions and improve dress intervals.